Industry Overview

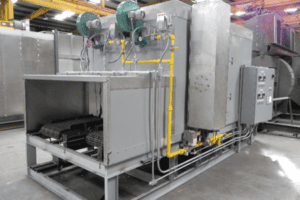

Epcon has provided innovative solutions to the Aerospace Industry, serving both civil and military aviation requirements around the globe. As a leading Supplier of proven Thermal Oxidation, Thermal Processing including Thermal Decontamination, Ovens & Furnaces and Finishing Systems, we have equipped the world leading aircraft manufacturers with quality systems – Ovens and Oxidizers for every stage of production, from the curing and heat treating of composite parts, to the finishing and painting final stages.

Characterized by the broad spectrum of applications, materials and processes, aerospace is a unique Industry, with aircraft carrier and airlines requiring the detailed documentation and compliance with stringent specifications. With decades of experience in executing complex projects in this industry, Epcon is your proven capable partner.

Patents & Proprietary Applications

- Ovens with integrated material handling for curing resins for advance aerospace composite applications

- Ovens for curing coatings for passenger and military airline parts

- Thermal Oxidizers for control of emissions from advanced fiber and web production (e.g. Carbon Fiber)

- Thermal Decontamination systems for hazardous material destruction/neutralization

These are just a few industry specific applications from the over 4,300 industrial systems Epcon has provided since its founding in 1977.